Introduction

You’ve decided to create a GHG inventory within your organization. Great! You’ve set your organizational and operational boundaries, selected your consolidation approach (equity share, financial control, or operational control), chosen a baseline year, and set up measures to mitigate double counting. Now what?

The following steps will help you identify and calculate your organization’s GHG emissions:

- Identify sources

- Select your calculation approach

- Collect data and choose emission factors

- Apply calculation tools

- Roll-up data to the corporate level

Identify Sources

There are four main categories for emissions, sources, according to the GHG Protocol: stationary combustion, mobile combustion, process emissions, and fugitive emissions.

Stationary combustion comes from fuel burned in stationary sources such as boilers and heaters. Mobile combustion comes from fuel burned during transportation such as the operation of cars, planes, and ships. Process emissions comes from physical or chemical processes such as cement calcination or aluminum smelting. Last but not least, fugitive emissions are derived from both the intentional and unintentional release of GHGs, including equipment leaks, cooling towers, CH4 (methane) from natural gas pipelines, and HCFs (hydrofluorocarbons) from air conditioning and refrigeration. Appendix D in the GHG Protocol’s Corporate Standard contains additional information on emissions by industry sector and scope.

Calculation Approach

The next step in the process of creating your GHG inventory is to select your calculation approach. There are three general approaches, according to the GHG Protocol: direct measurement, stoichiometric calculation, and estimation.

Direct measurement monitors GHG concentration and flow rate directly, such as with a filter on an exhaust pipe. A Continuous Emission Monitoring System (CEMS) is a device that continually collects information on the quantity of a gas being emitted. Using a CEMS to collect data provides an efficient way to continuously monitor stack emissions and automatically upload that data to the cloud. Note that CEMS are required under certain EPA regulations, so double check your local and industry standards!

Stoichiometric, or mass balance, calculations measures which elements enter and leave the system. Simply put, by accounting for material entering and leaving a system, mass flows can be identified which might have been otherwise unknown or difficult to measure. A simple application of the mass balance approach measures total carbon entering (through feedstocks, i.e. raw materials) and exiting (through products) a process then calculates the difference. This particular application assumes any carbon unaccounted for is either directly released or oxidized and released as CO2.

Estimation is the most common approach. Simply put, this entails multiplying activity data (e.g. fuel use records) by the appropriate emissions factor to get tonnes of emissions. Multiple this result by Global Warming Potential (GWP) to get total carbon dioxide equivalent (CO2e) of emissions.

What is Global Warming Potential?

GWP is a measure of how much a greenhouse gas contributes to global warming relative to CO2 (GWP of 1). A higher GWP means a higher capacity to warm the planet. Methane (CH4), for example, has a GWP of 21. That means it is 21 times more potent of a greenhouse gas than carbon dioxide. And that’s not even the half of it. Sulfur hexafluoride (SF6) has a GWP of 23,900 – nearly 24,000 times the potency of carbon dioxide!

100-year time horizon Global Warming Potential Values are available for download through the GHG Protocol. The table is adapted from the most recent IPCC Assessment Report.

Collect data and choose emission factors

Emission factors convert activity data to emission values. Activity data might include electricity use (kilowatt hours), distance traveled (kilometers), or gasoline used (gallons). Presented in specific units, this translates to pounds of CO2 per kWh of electricity, kilograms of CO2 per air kilometer traveled, and kilograms of CO2 per liter of petrol/gasoline, respectively. Always make sure units are consistent across measurements!

Find the latest Emission Factor Database (EFDB) from the Intergovernmental Panel on Climate Change (IPCC) website.

For most companies, Scope 1 direct emissions are calculated based on purchased quantities of commercial fuels (such as natural gas and heating oil) using published emission factors. Scope 2 indirect emissions are calculated from metered electricity consumption and supplier-specific, local grid, or other published emission factors. Sectors like manufacturing that require more specific methodologies can seek guidance on the GHG Protocol website or from industry associations (e.g., International Aluminum Institute, World Steel Association, WBCSD Sustainable Cement Initiative).

Tracking Scope 2 emissions

The GHG Protocol provides two methods for tracking Scope 2 emissions: the market-based method and the location-based method.

The location-based method calculates emissions based on the emissions intensity of the local grid area where the electricity usage occurs. The market-based method calculates emissions based on the electricity that organizations have chosen to purchase, often spelled out in contracts or instruments like Renewable Energy Certificates (RECs).

Sources should be prioritized as follows (1 being the preferred source):

Location-based:

- Regional or sub-national emission factors

- National production emission factors

Market-based:

- Electricity attribute certificates or equivalent instruments

- Contracts for electricity, such as power purchase agreements (PPAs)

- Supplier/utility emission rates

- Residual mix (sub-national or national)

- Other grid-average emission factors (sub-national or national)

Apply calculation tools

For companies, I highly recommend taking advantage of the cross-sector or sector-specific calculation tools available from the GHG Protocol. Cross-sector tools can be applied consistently across different industries, while sector-specific tools are unique to certain industries.

The table below, adapted from Table 3 in Chapter 6 of the Corporate Standard, describes the various tools available on the GHG Protocol website that reporting companies may use in their calculations. Each tool contains specific guidance on how to perform the calculation.

Cross-sector tools

| Calculation Tool | Main Features |

| Stationary Combustion | • Calculates direct and indirect CO2 emissions from fuel combustion in stationary equipment • Provides two options for allocating GHG emissions from a co-generation facility • Provides default fuel and national average electricity emission factors |

| Mobile Combustion | • Calculates direct and indirect CO2 emissions from fuel combustion in mobile sources • Provides calculations and emission factors for road, air, water, and rail transport |

| HFC from Air Conditioning and Refrigeration Use | • Calculates direct HFC emissions during manufacture, use and disposal of refrigeration and air conditioning equipment in commercial applications • Provides three calculation methodologies: a sales-based approach, a life cycle stage based approach, and an emission factor based approach |

| Measurement and Estimation Uncertainty for GHG Emissions | • Introduces the fundamentals of uncertainty analysis and quantification • Calculates statistical parameter uncertainties due to random errors related to calculation of GHG emissions • Automates the aggregation steps involved in developing a basic uncertainty assessment for GHG inventory data |

Sector-specific tools

| Calculation Tool | Main Features |

| Aluminum and other non-Ferrous Metals Production | • Calculates direct GHG emissions from aluminum production (CO2 from anode oxidation, PFC emissions from the “anode effect,” and SF6 used in non-ferrous metals production as a cover gas) |

| Iron and Steel | • Calculates direct GHG emissions (CO2) from oxidation of the reducing agent, from the calcination of the flux used in steel production, and from the removal of carbon from the iron ore and scrap steel used |

| Nitric Acid Manufacture | • Calculates direct GHG emissions (N2O) from the production of nitric acid |

| Ammonia Manufacture | • Calculates direct GHG emissions (CO2) from ammonia production. This is for the removal of carbon from the feedstock stream only; combustion emissions are calculated with the stationary combustion module |

| Adipic Acid Manufacture | • Calculates direct GHG emissions (N2O) from adipic acid production |

| Cement | • Calculates direct CO2 emissions from the calcination process in cement manufacturing (WBCSD tool also calculates combustion emissions) • Provides two calculation methodologies: the cement-based approach and the clinker-based approach |

| Lime | • Calculates direct GHG emissions from lime manufacturing (CO2 from the calcination process) |

| HFC-23 from HCFC-22 Production | • Calculates direct HFC-23 emissions from production of HCFC-22 |

| Pulp and Paper | • Calculates direct CO2, CH4, and N2O emissions from production of pulp and paper. This includes calculation of direct and indirect CO2 emissions from combustion of fossil fuels, bio-fuels, and waste products in stationary equipment |

| Semi-Conductor Wafer Production | • Calculates PFC emission from the production of semi-conductor wafers |

| Guide for Small Office-Based Organizations | • Calculates direct CO2 emissions from fuel use, indirect CO2 emissions from electricity consumption, and other indirect CO2 emissions from business travel and commuting |

Roll-up data to the corporate level

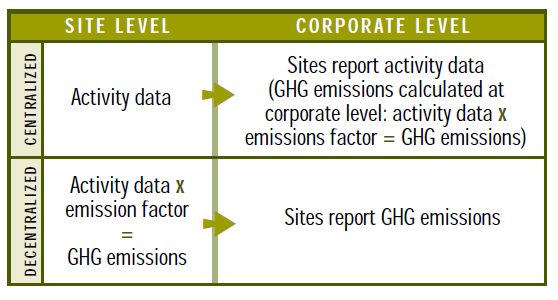

Once you’ve gathered your activity data, applied the appropriate emission factors, and leveraged a suitable calculation tool to obtain your company’s total carbon dioxide equivalent, it’s time to roll-up the data! There are two main approaches for rolling up GHG emissions data to corporate level: centralized and de-centralized.

With the centralized approach, individual facilities report activity/fuel use data (such as quantity of fuel used) to the corporate level, where GHG emissions are calculated. With the decentralized approach, individual facilities collect activity/fuel use data, directly calculate their own emissions, and report this data to the corporate level.

Approaches to gathering data from the GHG Protocol Corporate Standard.

The main difference between the two approaches is where the calculations occur and the type of quality management required. Responsibility for the initial data collection falls under facility-level staff, regardless of the approach. With the centralized approach, emission factors application and CO2e calculation is the responsibility of corporate staff. With the decentralized approach, it is the responsibility of facility-level staff. With the decentralized approach, lack of specialized knowledge in facility-level staff in GHG inventory development may hinder the efficiency and accuracy of calculations. This approach may be more suitable when local regulations require facility-level reporting. The centralized approach, on the other hand, allows the bulk of calculations to fall under the responsibility of specialized corporate staff with expertise on GHG inventory development. Companies can also use a combination of both approaches to balance accuracy and reporting efficiency.

Admiring your work

Creating a GHG inventory is a powerful step towards a greener future for organizations. By mastering the art of emissions calculation and data management, we’re not just ticking regulatory boxes—we’re paving the way for a more sustainable world. Appreciate your own effort, and that of your colleagues, as we take small steps every day in contributing to a healthier planet for generations to come.